Start-up cost for a printer may be expensive. Generally garments used for DTG printing should have at least 50 cotton to aid in the absorption of ink pigment for better quality.

Direct To Garment Printing Services And Their Advantages And Disadvantages

Compared to heat transfer printing the way that garments printed with DTG technology look is in a completely different league.

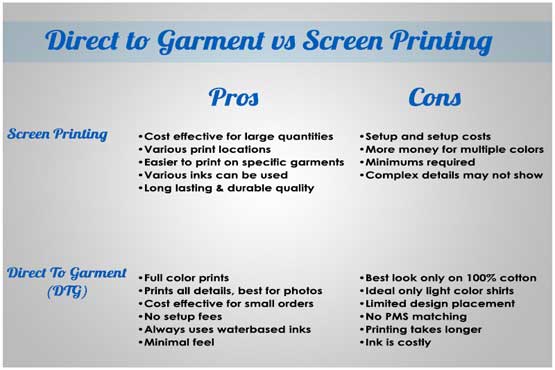

. Limited to cotton garments Limited to white garments Not cost-effective for mass production Can be a little slower than other methods. Direct to garment printing comes with a number of advantages and the two main advantages are speed and simplicity. Below are the few Direct to garment advantages over other traditional printing methods.

One of the biggest advantages for Direct to Garment Printing is that it makes smaller batch sizes and a design with tons of colors much more affordable. There are no setup costs as compared to Screen-Printing. The actual equipment the ink other consumables as well as maintenance can be costly especially if core focus is on printing on dark colored shirts.

Direct to Garment Printing Durability. There seem to be a couple disadvantages to the DTG process. Because of the ink that DTG printers use and the way that the ink is applied the end customer will eventually see the print fade significantly from repeated washing and drying.

Get A Free Heat Press With Purchase. Have you ever had customers who wanted to get t shirts printed for a special occasion only to be shut down by the costs that a t shirt screen printer has to charge for setup. The primary advantage of DTG printing is that its easy to produce one-offs.

The ink is not injected on top of material but fabric. Colours One of the major advantages of direct to garment printing is that it uses white inks. Can be used for detailed and broad designs.

Print images on direct to garment printers are highly accurate and detailed. This ink then soaks into the fibers of the clothing similar to the way ink is printed on paper. Doesnt work on all types of fabrics.

When a customer orders a single t-shirt from our shop. Some industry estimates say that DTG prints on garments last anywhere from. Payments As Low As 235Month.

Available for both mass production and short production runs. There is no other printing. To put it simply in very few words DTG printing is generally more expensive and slower than other methods.

Here are some of them. That isnt to say you cannot print high quantity runs on a DTG you certainly can but considering the amount of colors required and the production amount at some point it will be more economical to screen print. The top of the line Kornit Hexas are 350000 each.

Therefore you can wear your work uniforms with pride and show your audience that youre a professional and well-established outlet. Does DTG show detail. Have you ever had to have your customers radically adjust their t- shirt artwork in order to make it a limited number of colors in order to keep the.

Taking Screen Printing as an example. Large range of color options. Because garments are printed directly onto with an advanced inkjet printing process there is very little that the printing person actually needs to do.

Large range of colour options Can be used for detailed and broad designs Extremely fast process Available for both mass production and short production runs Low setup costs make it easy to access Works on coloured garments as well. This feature makes direct to garment one of the best garment printing strategy. Ad Garment Printer Ink - DTG Transfer Printer Embroidery Equipment.

Ad RICOH Ri Direct To Garment Printer Packages. Advantages of Direct-to-Garment DTG Printing. When printing onto a white jumper this will make little difference.

Low setup costs make it easy to access. With that said there are several reasons why you might prefer DTG printing over other kinds of garment printing. The Advantages of Direct to Garment Printing.

Small orders and one-offs print at a reasonable price. But when you start looking at blues and greens and even darker colours DTG definitely has the advantage here. DTG printing is a process that sprays ink directly onto a garment.

DTG printers are expensive. Clothing needs to be turned inside out before washing and requires a cold wash. The turnaround time for direct-to-garment printing is very short as it has a.

Direct to garment offers a large number of advantages over other traditional printing methods. Direct to Garment Printing is eco-friendly. Advantages of Direct to Garment.

All-Inclusive Direct-To-Garment Printer Packages. Compared to other methods direct to garment printing requires a little more aftercare. This scale of printing is not cost effective for large volumes of clothing.

Not the opposite that poor uniforms. You also shouldnt add extra spins to your wash cycle. Not optimal for large orders since the printing process can be slow and production costs stack up.

Other printing strategies are known to inject vinyl or ink on the material while direct to garment injects ink into the fabric. Ad Tips tricks and trends - find out more about the Print on Demand Drop Shipping industry. DTG ensures that high-quality printing is always carried out.

Low setup costs make it easy to access Works on coloured garments as well Accurate reproduction and high-quality results Water-based making it eco-friendly Can use digital software to create designs Disadvantages. The process begins by burning a negative design onto a screen which is then pressed against the shirt. There are limited options of placement for your design.

It is a clean process when compared to screen printing which requires considerable amounts of water and ink. DTG printing is most advantageous when performing high color prints on lower production runs. Advantages and disadvantages of DTG direct to garment printing Best for small on-demand order requests.

Print Quality The print quality of DTG printers is insane. In that case the final product have a different texture thus cant wear out easily or fade. Disadvantages of Direct-To-Garment Printing Although DTG has revolutionized the apparel industry it also has some disadvantages.

The average printer cost for a direct to garment inkjet printer is usually around fifteen hundred dollars. DTG also tends to be slower than other methods.

About Direct To Garment Print On T Shirts L A Dtg Printing

Advantages Disadavantages Of Dtg Printing Getbold

0 Comments